EMERALD AQUACHLOR

EMERALD AQUACHLOR — the world’s best water disinfection technology

EMERALD AQUACHLOR devices synthesize from water and table salt a highly effective and safe mixed oxidant solution for the disinfection of drinking water, seawater, wastewater and swimming pool water in any place and quantity.

Advantages:

- Water disinfection expense is at least 1.5 times cheaper compared to chlorine (Cl2),

- 3 times cheaper compared to sodium hypochlorite (NaOCl) and 10 times cheaper compared to ultraviolet (UV).

- Elimination of procurement, transportation and storage of disinfectants (including chlorine and sodium hypochlorite). Elimination of exclusion zones, reduced safety requirements.

- No chlorination by-products. No free volume of chlorine; all oxidants are dissolved in water.

- No corrosion of water pipes and no sludge formation in pipes.

- Prolonged disinfection effect in branched water distribution networks without the need for water ammonization.

- Destruction of biofilms on the inner surfaces of pipes, filter elements and storage tanks (the only solution in the world safe for humans and animals, capable of destroying biofilms).

- The absolute safety of AQUACHLOR devices has been confirmed by the German

certificate body TÜV RHEINLAND. - Possibility of chlorination dose reduction due to the high biocidal activity of the oxidant solution.

- Oxidant solution due to the synergy of the components has a disinfectant activity several times greater than chlorine and dozens of times greater than sodium hypochlorite.

Within 1 month of water disinfection with oxidant solution (instead of hydrogen peroxide), biofilms were removed from the inner surface of the tube.

Photo by BLUE SAFETY GmbH, Germany

|

Authorized agents for drinking water disinfection |

Main advantages and disadvantages | ||||||

| Efficiency | Safety |

Cost effectiveness |

Ease of use | Prolonged effect |

Low

concentration of by products |

Destruction of biofilms |

|

| AQUACHLOR (mixed oxidant solution) | YES | YES | YES | YES | YES | YES | YES |

| Gaseous chlorine | YES | NO | YES | NO | YES | NO | NO |

| Sodium hypochlorite | YES | YES | NO | NO | YES | NO | NO |

| Calcium hypochlorite | YES | YES | NO | NO | YES | NO | NO |

| Chlorine dioxide | YES | NO | NO | NO | YES | YES | NO |

| Оzone | YES | YES | NO | NO | NO | YES | NO |

| Ultraviolet | YES | YES | NO | YES | NO | YES | NO |

Completed project

76 units of AQUACHLOR 500 device have been disinfecting all drinking water in Balakovo City, Russia, since 2006. The devices produce more than 900 kg of oxidants per day in FAC* terms and disinfect 350,000 m3 per day.

5 units of AQUACHLOR 1000 devices in Aktau, Kazakhstan, have improved the quality of municipal wastewater disinfection and purification (16,000 m3 per day), operating on the new EMERALD TURBO technology. The total capacity of the devices is 120 kg per day of oxidant solution in FAC terms.

Water disinfection by an AQUACHLOR 500 device is used in a 2,500 m3 volume Olympic swimming pool in Minsk, Belarus. Purified water does not dry skin, does not irritate mucous membranes and is well tolerated by small children. No algae growth on the pool deck. No chlorine odor. No permanent pH adjustment is required.

Economic feasibility of EMERALD AQUACHLOR devices

| Basic criteria | Values | Notes |

|---|---|---|

| Disinfection costs of 1 m3 of water (at the chlorination rate of 1 g/liter) | $ 0.000485 | Water disinfection costs is at least 1.5 times cheaper compared to chlorine (Cl2), 3 times cheaper compared to sodium hypochlorite (NaOCl) and 10 times cheaper compared to ultraviolet (UV). |

| Power consumption per 1 kg of oxidants (FAC), no more than | 4 kW | |

| Table salt consumption per 1 kg of oxidants (FAC), no more than | 2 kg | |

| No replaceable or fast-wearing parts | Yes | The main components are durable and resistant to wear and tear. |

| Average production cost of 1,000 kg of oxidants (FAC | $ 485 | At least 1.5 times less than the average cost of chlorine gas sold in cylinders and 2.5 times less than the cost of sodium hypochlorite in FAC terms. |

| Average payback period (ROI) | 2 years | |

| Average device lifespan | 12 years | In total: 10 years of profit + preserving the Planet’s ecology! |

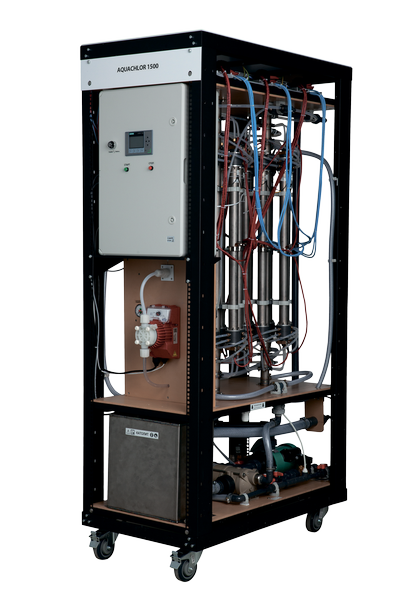

EMERALD AQUACHLOR devices product line

| Model | Oxidants capacity (FAC, Cl2), g/h | Caustic soda capacity (NaOH), g/h | Power consumption, no more than, W | Table salt con-sumption (NaCl), no more than, g/h | Dimensions, WxHxD, mm | Net weight, kg |

| EMERALD AQUACHLOR 250 | 250 | 283 | 1,200 | 500 | 600х1800х8 | 110 |

| EMERALD AQUACHLOR 500 | 500 | 567 | 2,300 | 1,000 | 600х1800х800 | 120 |

| EMERALD AQUACHLOR 1000 | 1000 | 1,133 | 4,500 | 2,000 | 600х2000х750 | 130 |

| EMERALD AQUACHLOR 1500 | 1500 | 1,700 | 7,000 | 3,000 | 600х2000х1000 | 150 |

| EMERALD AQUACHLOR 2000 | 2000 | 2,260 | 9,000 | 4,000 | 700х2000х1150 | 170 |

| EMERALD AQUACHLOR 3000 | 3000 | 3,400 | 14,500 | 6,000 | 700х2000х145 | 200 |