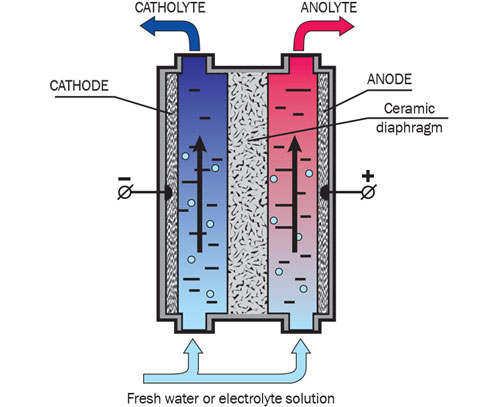

EMERALD devices are based on electrochemical activation technology (ECA). The essence of ECA technology consists in electrochemical synthesis and subsequent use of electrochemically activated (metastable) substances instead of traditional stable reagents.

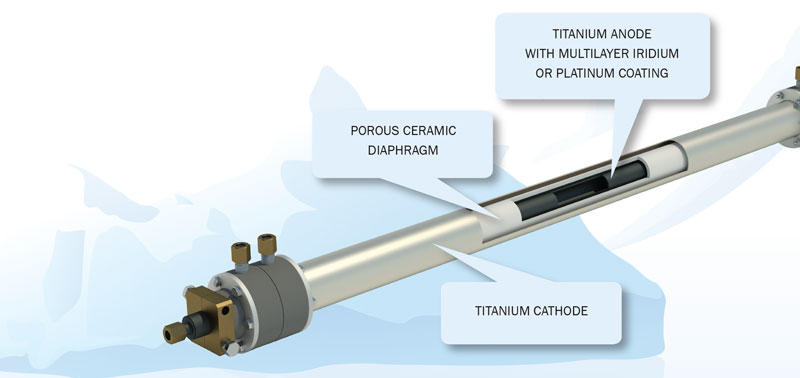

The main working element of EMERALD devices is the electrochemical Bakhir Module (MB element) with a porous ceramic diaphragm. MB electrochemical modules are protected by patents № RU 2350692; USA 8,961,750; UK 2479286.

EMERALD devices are developed and manufactured in R&D partnership with the Vitold Bakhir Electrochemical Systems and Technologies Institute — the world’s leading scientific center in the field of electrochemical activation. More than 50 years of experience and modern discoveries have made it possible to manufacture EMERALD devices unrivaled throughout the world in terms of their technical features.

More than 50 years of experience

More than 400 patents registered<br /> in 50 countries

More than 2,500,000 authentic MB elements have been manufactured

Reliability, efficient power consumption and modularity of MB elements enable the manufacture of a variety of devices to suit each specific case.

Prof., Dr. of Science, Author of ECA technolog

- 60 liters per hour

- 2 MB-11 elements

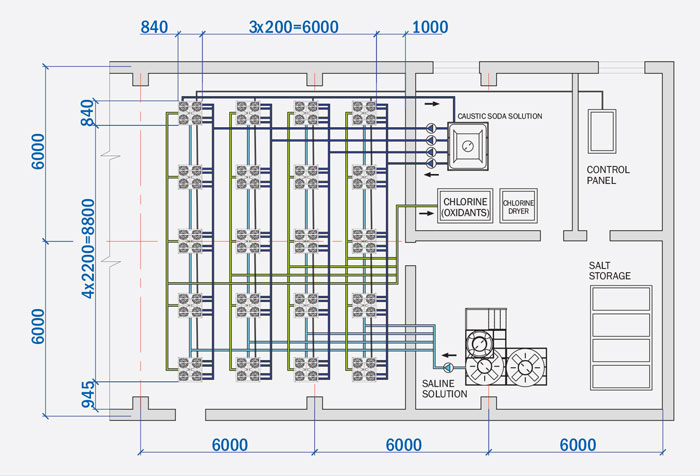

- 2,000 m3 per hour (2.0 kg/h FAC capacity*)

- 16 MB-26 elements

*Capacity in terms of free available chlorine

- 120.0 kg/h FAC capacity

- 960 MB-26 elements

Electrochemical mb elements advantages:

- The ceramic diaphragms do not require periodic replacement and can be easily washed with any common acids (citric, acetic, hydrochloric or phosphoric) in case of impurities.

- MB elements service life is more than 50,000 hours of continuous work.

- Wide possible concentration of source electrolytes: from 0.001 to 10 mol per liter.

- Automatic anode cooling and self-cleaning of the diaphragm and cathode chamber

“To strengthen cooperation of the BRICS countries in the areas of activities related to industrial production of the most important products of the chemical industry (chlorine, caustic soda, persulfuric acid, hydrogen peroxide) at the places of consumption, as well as for reagent[1]free regulation of physical and chemical properties of water and aqueous solutions, through the use of electrochemical activation in technological processes…”